Not every warehouse needs the same level of impact protection. While single-height guardrails may be sufficient in low-traffic areas, they often fail in zones where forklifts, pallet jacks, and heavy equipment operate at speed. This is where double height guardrails become essential.

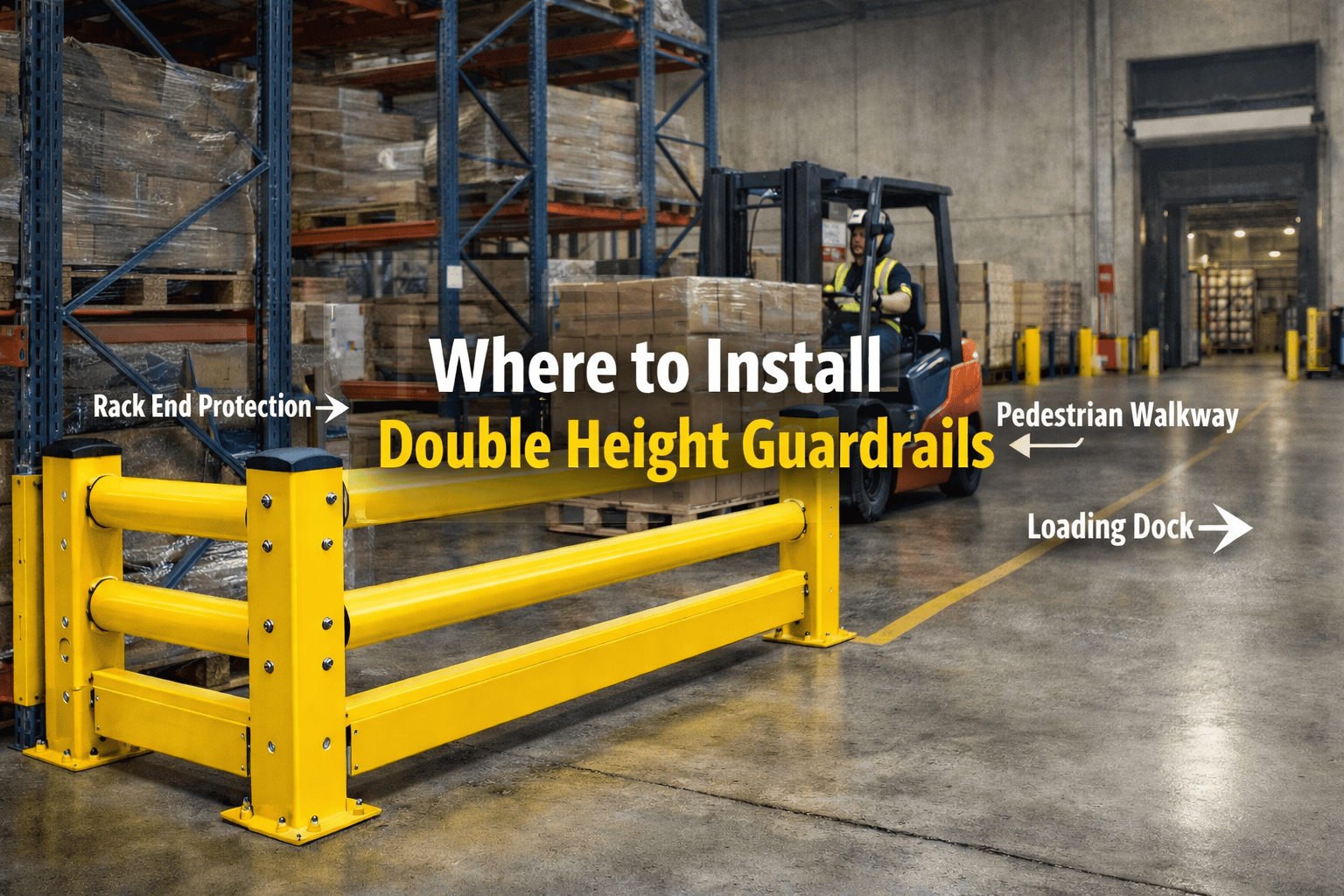

If you are already considering double height guardrails, the real question usually isn’t what they are — it’s where they should be installed to justify the investment and maximize safety. This guide breaks down the exact warehouse locations where double height guardrails provide the most value and protection.

Why Location Matters for Double Height Guardrails

Double height guardrails are designed to:

-

Absorb higher impact forces

-

Prevent forklifts from climbing or overriding a single rail

-

Provide extended vertical coverage for equipment and pedestrians

Installing them in the wrong place can lead to overspending. Installing them in the right place can prevent rack collapse, structural damage, and serious injuries.

1. High-Impact Forklift Traffic Zones

Best use case for double height guardrails

Forklift aisles with frequent, high-speed movement are the most common failure point for standard guardrails. In these areas, a single rail often absorbs only the lower impact, allowing the forklift mast or forks to ride up and cause damage.

Why double height guardrails are needed here:

-

Forklifts strike at multiple impact points

-

Higher rail prevents equipment override

-

Reduces damage to walls, columns, and assets

Typical locations:

-

Main forklift travel aisles

-

Cross-aisle intersections

-

Narrow turning zones

👉 Ideal product type: Heavy-duty double height guardrail starter kits with add-on sections for long runs.

2. Rack End Protection Areas

Rack ends are among the most frequently damaged structures in warehouses. Even low-speed impacts can compromise rack stability over time.

Why double height guardrails outperform single rails:

-

Protect both rack legs and upper beams

-

Reduce long-term structural fatigue

-

Prevent cascading rack failures

Common scenarios:

-

End-of-aisle pallet storage

-

Selective and push-back racking systems

-

High-density storage zones

Installing double height guardrails here acts as a secondary safety layer, especially in facilities with frequent pallet handling.

3. Pedestrian Walkways Near Vehicle Traffic

Pedestrian safety is one of the strongest reasons facilities upgrade to double height guardrails.

Single rails may stop a forklift, but they do little to:

-

Visually separate people from equipment

-

Prevent forklifts from tipping or riding up toward pedestrians

Double height guardrails provide:

-

Clear physical and visual separation

-

Increased stopping height for equipment

-

Compliance support for safety audits

Recommended installation areas:

-

Marked pedestrian walkways

-

Crosswalks near forklift routes

-

Workstations adjacent to traffic lanes

👉 This is especially critical in mixed-use warehouses where foot traffic and equipment operate simultaneously.

4. Loading Docks & Dock Door Approaches

Loading docks are high-risk zones due to:

-

Tight maneuvering space

-

Repeated forklift acceleration and braking

-

Poor visibility during loading operations

Why double height guardrails are ideal:

-

Prevent forklifts from striking dock walls

-

Protect dock door frames and controls

-

Reduce costly downtime caused by impact damage

Key locations to protect:

-

Dock door sides

-

Staging lanes near dock edges

-

Equipment waiting areas

In many facilities, double height guardrails near docks pay for themselves by reducing maintenance and repair costs.

5. Building Columns & Structural Supports

Structural columns are expensive to repair and critical to building integrity. A single severe impact can cause long-term issues.

Double height guardrails help by:

-

Shielding columns at multiple heights

-

Absorbing repeated minor impacts

-

Preventing direct contact with structural steel

Where this matters most:

-

Central warehouse columns

-

Columns near turning zones

-

Columns along main traffic lanes

How to Decide If Double Height Guardrails Are Necessary

Ask these questions when reviewing your layout:

-

Do forklifts operate at moderate to high speeds here?

-

Is there frequent turning, reversing, or blind movement?

-

Are pedestrians or workstations nearby?

-

Would a single rail fail if struck above fork height?

If the answer is yes to two or more, a double height guardrail system is usually the correct solution.

Using Starter Kits and Add-On Kits Strategically

One advantage of modern double height guardrail systems is modularity.

Best practice:

-

Use starter kits for corners and new protection zones

-

Extend protection using add-on kits for continuous runs

-

Mix configurations to match your warehouse layout

This approach keeps costs controlled while maintaining consistent protection across critical areas.

Final Thoughts: Install Where Risk Is Highest

Double height guardrails are not meant to replace every barrier in a warehouse. They are meant to be installed where failure would be costly, dangerous, or unavoidable.

By focusing on:

-

Forklift impact zones

-

Rack ends

-

Pedestrian interfaces

-

Loading docks

-

Structural supports

you ensure that your investment delivers real safety improvements and long-term cost savings.

If you’re evaluating options, explore double height guardrail starter kits and add-on systems designed for high-impact warehouse environments to match your layout and risk profile.